Working with architects and the main contractor, Acorn Aluminium has successfully brought Victorian-period detailing to the design of a contemporary student accommodation scheme in the heart of Leeds.

A student accommodation project with heritage roots

Designed by architects Cartwright Pickard, Leonardo Budlings is a £62 million student accommodation scheme in the centre of Leeds by McLaren Property.

In addition to the adaptation of 1990s office space to residential, it includes the conversion of Grade II listed Victorian print works.

Acorn Aluminium was appointed to the 473-bed project by main contractor Robertson Construction to design, manufacture and install, more than 4,000m2 of curtain walling and windows to the scheme, starting on-site at the end of last year.

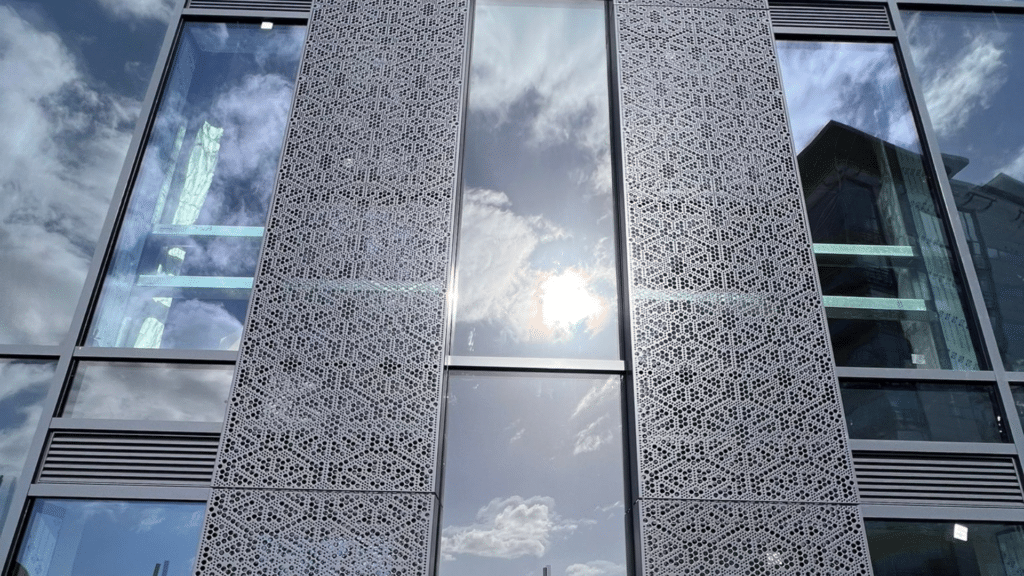

In addition to the glazing elements of the scheme, the design also encompassed perforated external façade panels, the design of which were inspired by ornate Victorian tiling found within the original Leonardo Buildings’ main staircase.

Manufactured in a striking teal blue and unique to the building, the original tiles featured ornate leaf work and flowers in a repeating pattern.

Balancing design and function

“The perforated panels sit over the face of some of our products”, explains Craig Key, Operations Manager, Acorn Aluminium.

“It makes up a key element of the design but is also there for internal guarding and to prevent falls where there is an openable window behind.

“The architects had picked up on the fine detailing in the design that they wanted to move forward with and we then worked with them and a specialist fabricator appointed by us, to evolve those designs to something which could be manufactured without compromising the structural integrity of the panel.”

An evolving design

While the ornate of the original Victorian tiles create a striking entrance to the original building, the same level of detail could not be replicated in the perforated panel without compromising its performance.

This meant an evolution of the design, simplifying and then creating a repeating pattern which harmonised design and structural performance.

Manufactured in 3mm sheet steel, this creates an open area of around 52%, while retaining the structural strength to fulfil containment requirements.

Leonardo Buildings perforated panel design overview

- Two perforation sizes: 10mm and 20mm diameters, with larger perforations introduced to reduce manufacturing time

- Triangular grid at 60degrees

- 20mm solid boundary to perimeter

- 3mm sheet thickness

- Pearl Beige powder coated finish (RAL:1035)

“There is this fine balance that you need to achieve. You need to remove enough of the panel to provide adequate ventilation and to achieve the pattern, but make sure enough of it is retained so it retains structural integrity.

“To get that balance right we also worked closely with specialist engineers to do the calculations, not remove too much and use the right fixings and at the right frequency to guarantee lifetime performance and to successfully complete barrier load testing.”

Craig Key, Operations Manager

The increasing popularity of perforated panels in commercial projects

“Perforated panels are seeing major growth”, Craig continues. “They feature in some form on the majority of the projects we work on but particularly in the student accommodation sector”, he explains.

“In addition to performing a critical safety function and providing effective ventilation, they can often define the overall appearance of the scheme and are very dynamic.

“At night when the building behind is lit they completely redefine its appearance, and are a very effective design feature.”

Energy-efficient aluminium windows and curtain walling

The perforated panels at the Leonardo Budlings sit in front of 466 tilt-and-turn windows across six storeys, designed, manufactured and installed by Acorn Aluminium.

Acorn Aluminium also supplied fully capped curtain walling to the scheme in Senior Architectural Systems flexible and highly energy efficient SF52 system.

FACTBOX:

Senior Systems SF52 aluminium curtain walling:

- Can be assembled in any combination of capped, vertically capped, horizontally capped or silicone glazed to create a unique external facade. A variety of caps allows even more aesthetic possibilities.

- Choose from Zone drained or Mullion drained (fully capped only).

- Large range of transom & mullion sizes with additional reinforcing sleeves and boxes from 50-250mm plus the option of concealed steel reinforcing to allow larger spans.

- Raked heads for a range of apex angles can be achieved using a specially designed shear block.

- Fully compatible with any of our windows (including frameless vents) plus both manual and automated doors.

- Available in an almost unlimited choice of colours and finishes both externally and internally.

Senior Systems SPW600 aluminium commercial window system

- Energy efficient three chamber 75mm system using Polyamide thermal breaking technologies to deliver an enhanced level of thermal performance

- Available in top and side hung casement options including inward opening and tilt-and-turn options

- Achieves a BFRC A Rating

- U-values as low as 1.3W/m2K

- Enhanced security Secured by Design compliant option

In addition to an advanced level of thermal performance and solar control, the glass specification also includes a high level of acoustic control with a 42RW+CTR rating, significantly reducing traffic noise.

Construction is due for completion by August 2023 in time for the 2023/2024 academic year.

For more about Acorn Aluminium please call 0115 928 2166, email [email protected] or visit www.acornalumnium.com